Looking for a substitute to resin filler

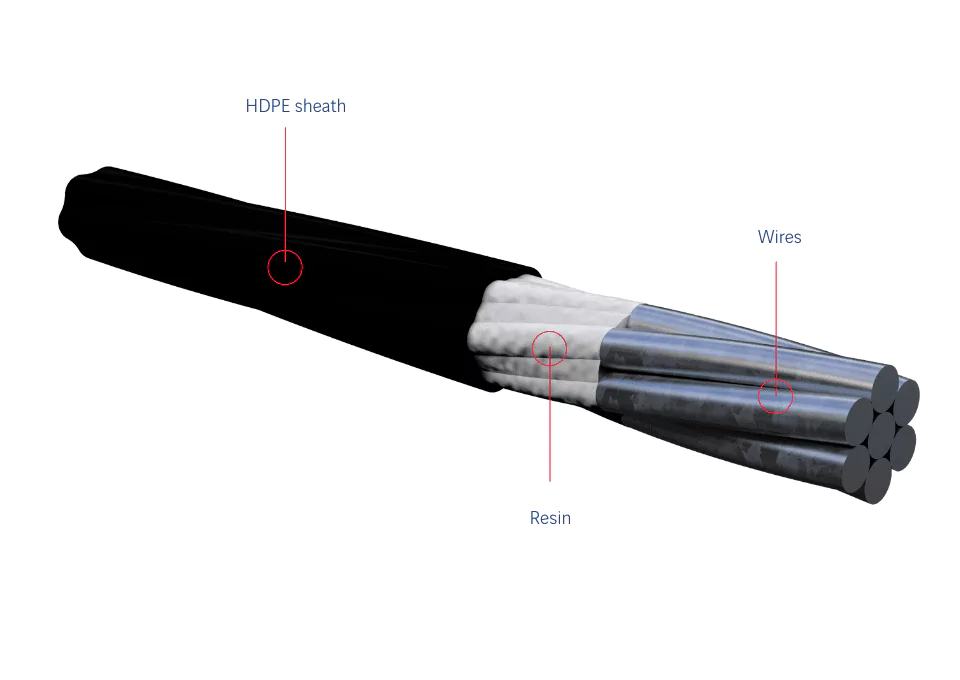

Freyssinet developed the patented Cohestrand® technology to overcome issues of force transfer and mechanical strength that a “conventional” waxed sheathed strand cannot withstand, and so avoid any slippage between the strand and its sheath. The resin binds the wires together to enable them to act as a single unit, transmitting more effectively axial forces into the saddle and the tower. But from a performance point of view, the resin filler is only necessary for the short length of strand that is confined within the saddle, where the load transfer takes place. The 200 m long strand needed for Cua Dai bridge required then only resin over a length of around 5 m in the middle of the strand which will be within the tower saddle unit. The extra cost and environmental impact of using resin across the full strand length made it difficult for Freyssinet to be competitive with other suppliers on the extradosed bridge market.