Operational excellence

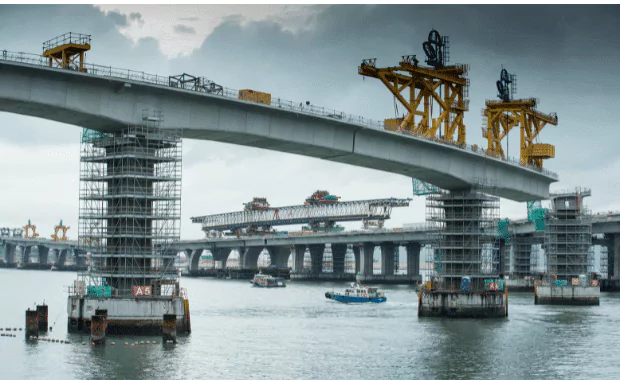

Although complex to assemble, the gantry is a powerful piece of machinery which can erect a pair of segments in few hours. The equipment being fully autonomous, the segment erection cycle could be split in short periods adapted to the short traffic closure granted by Highways and MTR.

Segments were secured by post-tensioning bars

We had to erect and secure segments above carriageways in a time frame of 3 hours. Segments were secured by post-tensioning bars, prior to installing cantilever PT tendons ensuring a fully safe and controlled process compatible with the high safety expectation of Highways and MTR authority for works being carried out above traffic.